HYDRAULIC PRESSES FOR BRASS AND ALUMINIUM FORGING

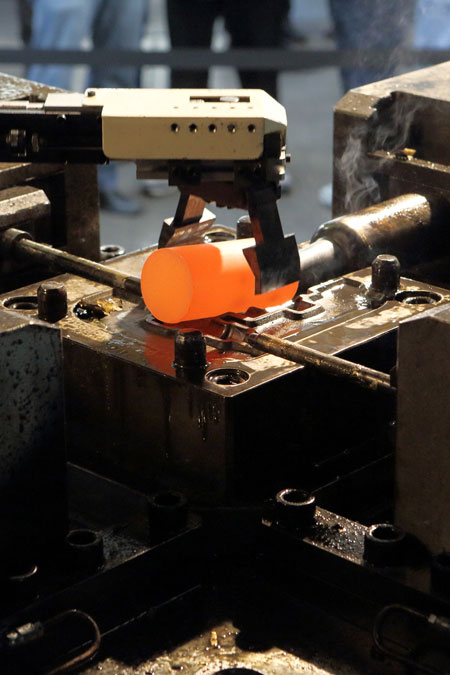

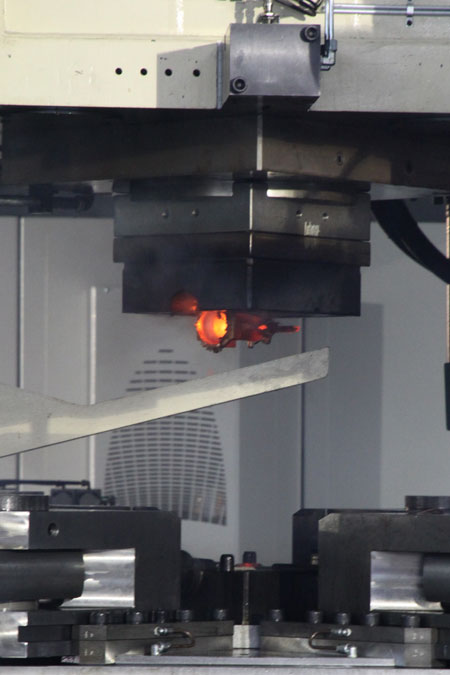

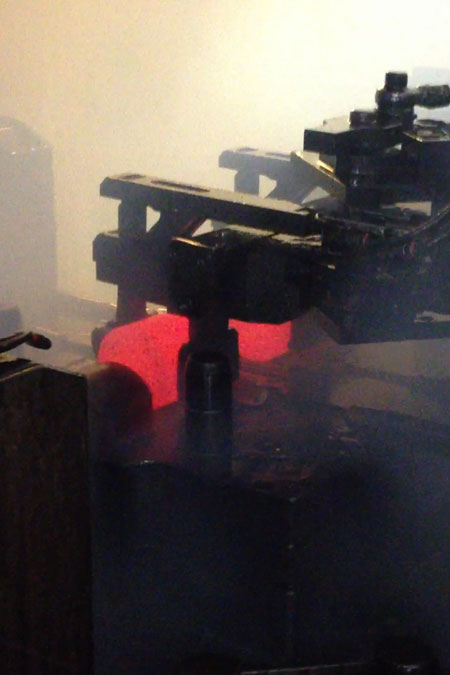

Besides the mechanical presses, a new patented Hydromec HFH hydraulic press has been added, for the hot forging of brass and aluminium items, designed with several innovations, among which the quick automatic change of the sub-presses and the possibility of obtaining lighter and flash-less pieces.

It can grant performances that would require a 100% higher capacity with a traditional mechanical press compared to the new Hydromec hydraulic press: as a matter of fact, the performances of the 400 ton model can be compared to a mechanical press of about a 800 ton capacity.

Technical solutions have been patented to reduce energy consumption, with the employment of oil quantities reduced to a fifth compared to the currently produced presses.

The hydraulic presses of the series HFA are designed within a range from 2.000 kN to 10.000 kN, to forge flat pieces, usually obtained on friction-screw presses, core-horizontal pieces by means of two-impression dies, with multiple orthogonal or angular punching, independent adjustments of strokes and forces, automatic sub-press change, lubrication and die cooling integrated in the system.